Universal machines type UM60 are useful for cutting, mixing, kneading, emulsifying ; only one Stephan® machine for several processes. It means one investment, an optimal using of the machine and a flexible planning of production. Thanks to its different executions and full additionnal equipments, the Stephan® machine is perfectly fitting to the needs of all branches.

The Stephan universal machines are easy handling. They are the result of a long experience and a continous technical development. A modern process of fabrication and raw materials of quality insure a reliable and robust machine. With a speed rotation of 1500 and 3000 per minute, soft, hard, stringy, viscous or dry materials are intensively worked and changed into an homogeneous product.

A supplementary rotative movement is obtained by the higher mixing baffle that scraps the jacket of the bowl and the cover and bring them back to the knives. Indeed, all the ingredients of the recipe are regularly spreaded and mixed.

Times of process faster, the several using and the easy handling of the Stephan® machine rationalize work processes and bring to a better profitability.

Description of the machine

- Bowl size : 60 liters

- Capacity : De 8 à 40 liters max

- Dimensions : Length 1290 x Width 1495 x Height 1600 mm

- Weight : 250 kg

- Working temperature : 95°C maximum

- Working pressure : 0 bar

- Parts in contact with the product : Stainless steel V2A

- Machine chassis : Stainless steel V2A Drive :

- With motor hood directly flanged at the bowl with direct drive of knife shaft

- Speed : 1500 / 3000 or 750 / 1500 / 3000 t/min

- Power : 5.5 / 7.5, 6.6 / 9.0 (renforced) ou 2.2 / 4.0 / 5.5 kW

- Operation voltage : 400 V , 50 Hz

- Control voltage : 24 V

- Power requirement : From 7 to 101 kW / 20 to 25 A curve D

- Brake : Disc brake for main motor

- Emergency button

- Stainless steel cover

- Motor drive with flange linked to the cover

- Polyamid mixing arm or in stainless steel with scraper

- Stainless steel knife shaft plugged and fixed at knife shaft with 2 knives

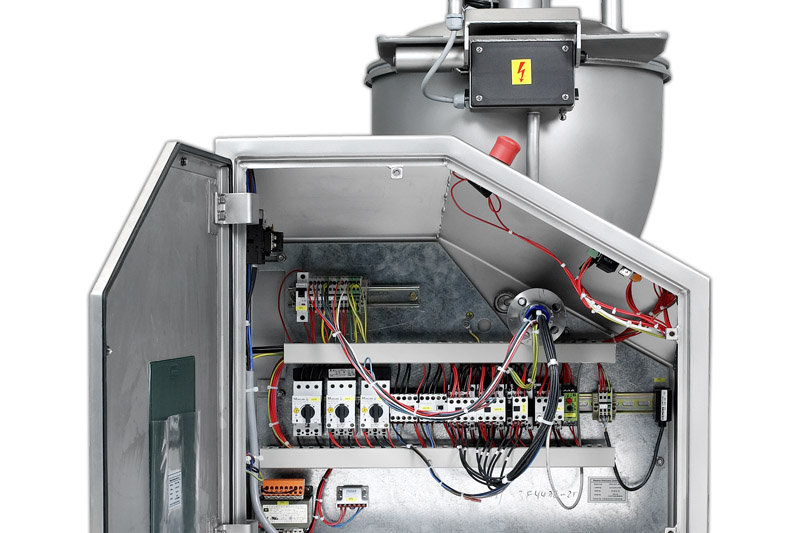

- Stainless steel bowl on the main drive. Manually removable for the emptying of the product Electrical equipment :

- Soft touch keybord 3011 for main motor, temperature display and for working process time by switch.

- Vacuum pump

- Double jacket

- Temperature feeler

- Frequency control

- Reinforced motor

- Tools.

- Inside chocolates

- Solid mixing

- Almond paste

- Suspension

- Chocolate

- Emulsions

- Ganache

- Topping

- Praline

- Creams

- Paste...